|

In the quest to develop higher-capacity, longer-lasting batteries, the focus is typically on materials or fabrication techniques. While developing a new way to study and observe battery performance in realtime, a team of researchers from the University of Maryland also discovered that by altering how their battery was charged, they could increase its capacity. The results are reported in the November 25 online issue of Advanced Energy Materials.

Together with collaborators at Monash University, Department of Materials Science and Engineering (MSE) professor Liangbing Hu and his research group at the University of Maryland Energy Research Center are the first to measure the optical and electrical transport properties of the individual nanoflakes that make up a battery’s electrode while it is being charged.

“Conventional measurement techniques reveal the electrochemical and mechanical properties of the entire electrode,” explains MSE graduate student Jiayu Wan, a member of Hu’s research group and the first author of the paper, “but they can’t be used to the measure electrical properties of individual electrode flakes. Our new microbattery platform does. It reveals equally important, if not more important, information that we need to make better batteries.”

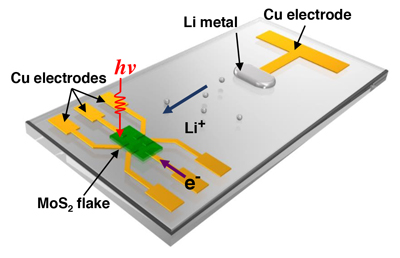

Wan, Hu and their colleagues wouldn’t be able to do it with any battery off the shelf. The key to their technique was designing one that could be simultaneously observed and charged in a device called a probe station, which measures electric transport properties. They created a planar (flat) lithum-ion microbattery with electrodes made of two dimensional molybdenum disulfide (MoS2) crystals, a material currently being studied for use in photonic, optoelectronic and energy devices.

Schematic of the MoS2-Li microbattery.

Wan and research associate Wenzhong Bao (MSE/Physics) were testing the resistance of the new battery’s electrodes at the nanoflake level when they realized that the way in which it was charged could be as important as how it was made.

“While we were developing our measurement process, we discovered a novel rapid charging technique that led to enhanced conductivity and three times the capacity than when the same battery was traditionally charged,” Wan explains. “We’re the first group to demonstrate this. There have been studies associating charging speed with how long a battery lasts, but not with its energy storage capacity.”

For now, Wan says, the application of the charging technique is limited to Li-ion batteries made with MoS2, but the team is continuing its research, searching for other compatible battery configurations and electrodes.

Bao, Hu and Wan’s collaborators include Professor Michael Fuhrer (Monash University, Australia); Hu Group members Jiaqi Dai, Fei Shen, Lihui Zhou, Daniel Urban, and Yuanyuan Li; Yang Liu and Katherine Jungjohann (Sandia National Laboratories); and Xinghan Cai (Department of Physics, University of Maryland).

For More Information:

Jiayu Wan, Wenzhong Bao, Yang Liu, Jiaqi Dai, Fei Shen, Lihui Zhou, Xinghan Cai, Daniel Urban, Yuanyuan Li, Katherine Jungjohann, Michael S. Fuhrer, Liangbing Hu. “In situ Investigations of Li-MoS2 With Planar Batteries.” Advanced Energy Materials. Published online 25 Novermber 2014 (print edition forthcoming). DOI: 10.1002/aenm.201401742. Abstract

Visit Professor Hu’s web site

Related Articles:

ION honored by federal and state officials

“Build Our Future” grants include two MEI2 energy companies

Maryland’s first-ever solid-state battery pilot production line launches

$15M Federal Grant Awarded to Support Maryland Electric Vehicle Charging Network

Transformative Battery Structure Surpasses US’ Fast Charge Goals

Powering a Greener Future

2023 Energy Seed Grants Provide Launchpad for Local Startups

Energy Consortium promotes science and innovation

MPT State Circle Highlights UMD Innovative Energy Technology

Rethinking the Architecture of Solid-State Batteries: ION Closes $30M Investment Round

December 1, 2014

|